In the world of industrial vehicles and automated guided vehicles (AGVs), tire selection is a critical factor that directly impacts performance, durability, safety, and overall operating costs. Among the most common non-pneumatic tire types are:

- Solid Rubber Tires

- Press-On Solid Tires

- Polyurethane Solid Tires

Each of these tire types offers unique benefits and limitations depending on the application scenario. This article provides a detailed comparison and selection guide to help you make the best decision for your AGV or material handling equipment.

1. Solid Rubber Tires – Heavy-Duty Basic Option

Solid rubber tires are made entirely of vulcanized rubber and mounted directly onto the wheel rim without an inner tube. They are known for their ruggedness and ability to operate in tough environments.

✅ Advantages:

- Maintenance-Free: No risk of punctures or air pressure loss. Ideal for construction sites, mines, and debris-prone areas.

- High Load Capacity: Can support static loads of over 11 tons (e.g., 14.00–24 tire size).

- Wide Temperature Range: Operates reliably from -40°C to +100°C; resistant to oil and chemical corrosion.

⚠ Limitations:

- Poor ride comfort due to low elasticity

- High rolling resistance and energy consumption

- Not suitable for speeds above 25 km/h due to heat buildup

Best For: Bulldozers, mining vehicles, fixed-position heavy equipment

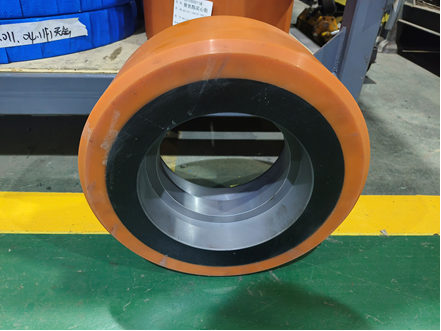

2. Press-On Solid Tires – High Precision for Industrial Vehicles

Press-on tires feature a layered construction with a rubber tread bonded to a steel base ring. They are mounted using an interference fit (±0.64 mm), making them ideal for indoor or precision applications.

✅ Advantages:

- Secure Fit: Eliminates risk of tire slippage, especially under frequent steering or load changes

- Application-Specific Options: Anti-static, non-marking, oil-resistant, cold-resistant, etc.

- Heat Dissipation: High-end models include heat-reducing vent designs for continuous use

⚠ Limitations:

- Higher manufacturing cost due to precise steel ring machining

- Complex to replace; requires special tools and skilled labor

Best For: Electric forklifts, port tow tractors, in-plant transport AGVs

3. Polyurethane Solid Tires – Lightweight, High Performance

✅ Advantages:

Made from synthetic polyether or polyester-based elastomers, polyurethane tires combine excellent wear resistance with chemical and thermal stability, making them suitable for high-end logistics and clean environments.

- Lightweight & Durable: Up to 15% lighter than rubber, 3x longer lifespan

- Superior Dynamic Performance: Generates less heat at high speeds

- Environmental Adaptability: Excellent resistance to hydrolysis, UV exposure, and harsh chemicals

⚠ Limitations:

- Higher cost (1.5–2x rubber tires) due to material and production complexity

- Slightly lower grip on wet surfaces unless tread is optimized

Best For: Cold storage vehicles, airport baggage AGVs, cleanroom logistics

Quick Comparison Chart

| Feature | Solid Rubber | Press-On Tire | Polyurethane |

| Load Capacity | Very High (>10T) | High (for forklifts) | Medium-High |

| Rolling Resistance | High | Medium-High | Low (energy-saving) |

| Wear Life | 1–3 years | 3–5 years | 5–8 years |

| Cost | Low | Medium | High |

| Speed Rating | ≤25 km/h | ≤25 km/h | ≤40 km/h |

| Best Use | Mining, Dozers | Forklifts, Trailers | Cleanrooms, Cold Chain |

Selection Tips

- For heavy loads + low cost, choose solid rubber

- For precision industrial use, go with press-on tires

- For high-frequency or long-life operations, polyurethane is the best fit

Conclusion: Match Tires to Your Operating Conditions

Each tire type has its place in industrial logistics. Whether you’re managing a fleet of AGVs in a clean factory or supporting rugged outdoor operations, the key is to match tire features to your working conditions — not just aim for the most advanced material.

As material science continues to evolve, innovations such as nanocomposite polyurethane and lightweight steel rings will further expand the capabilities of solid tires in smart logistics.

🔍 Looking for a customized AGV solution with the right tire setup?

At HENSEN, we don’t just manufacture AGVs — we engineer complete transport solutions, including load-specific tire configurations tailored to your application.

📩 Contact us today to discuss your project needs.

Leave a comment