If you’re also facing challenges in transporting extra-long pipelines or oversized industrial materials, especially under space limitations, complex workflows, or tight budget constraints, don’t worry, this real-world case study may offer the insights and inspiration you need.

Project Overview:

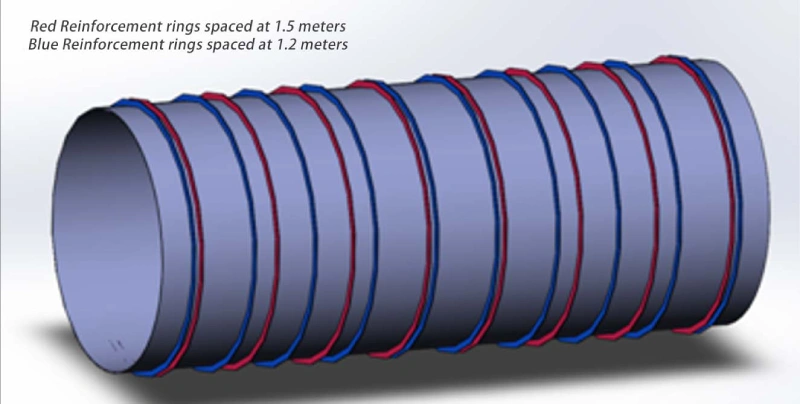

A leading pipeline manufacturer undertaking a major hydropower project turned to HENSEN for help. The project required the transportation of extra-large steel pipes, with diameters of 4,800 mm, lengths of 12 m and 15 m, and weights of up to 36 tons.

Complicating matters further, the pipes featured central reinforcement rings that must not be impacted, and the working environment had narrow aisles, as well as height restrictions in the painting room.

The client needed an automated guided vehicle (AGV) capable of:

- Transporting oversized pipes with high maneuverability,

- Navigating tight indoor/outdoor spaces with sloped access,

- Offering manual and remote-controlled operation,

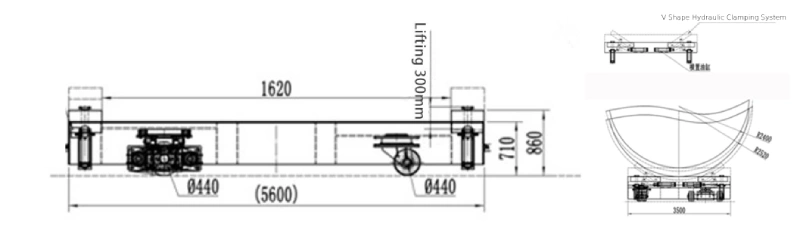

- Lifting the pipes at least 300mm during processing steps without material slippage.

Forklifts, cranes, and trucks all failed to meet these complex transport needs—until they found HENSEN.

HENSEN’s Analysis & Challenge Breakdown

With over 20 years of experience in heavy-duty industrial transport, HENSEN understood the key technical challenges:

- Extreme Maneuverability: The 12–15m pipelines must move through tight corridors, be positioned precisely, and be transferred laterally into processing stations.

- Semi-Automation: The client needed a cost-effective transport system—not full automation, but one that reduces labor while maintaining control.

- Incline Adaptability: The AGV had to traverse indoor factory floors, outdoor cement roads, and ramps near workshop doors.

- Low-Profile Vehicle Body: Height limits at each station required the AGV to be ultra-low yet still capable of slope-climbing and material elevation.

- Safe Pipe Handling: The pipes couldn’t roll or fall during transfer, and lifting controls had to be remote-operated for flexible use.

HENSEN’s Tailored AGV Solution:

1. Recessed Platform Design for Pipe Protection:

To avoid damaging the reinforcement rings, HENSEN created a central recessed platform (150mm deep) to accommodate both pipe sizes securely while ensuring the entire platform height remains low enough to pass under roller conveyors.

2. Hydraulic Clamping System:

To maintain pipe stability during elevation and movement, hydraulic barriers were installed. These lift remotely to secure the pipe in place, and lower again during unloading, ensuring safe and smooth operations.

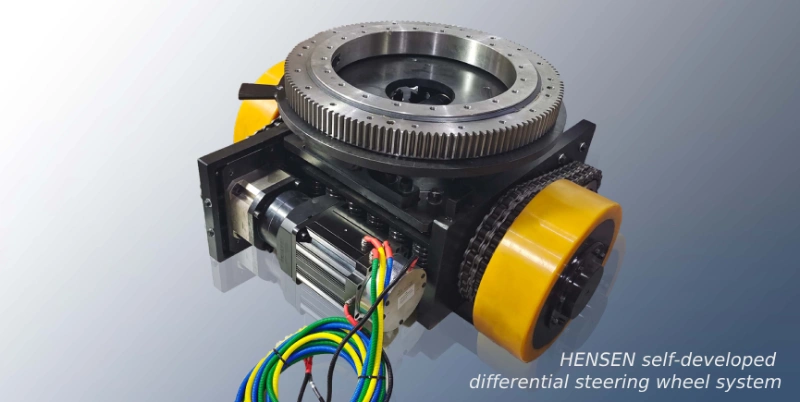

3. Advanced Steering with Proprietary Differential Swivel Wheels:

At the heart of HENSEN’s design is its self-developed differential steering wheel system, enabling:

- 360° in-place rotation,

- Lateral (sideways) and longitudinal motion,

- Crab-walking capabilities for narrow environments.

Compared to traditional horizontal steering wheels, HENSEN’s system offers better traction, ramp climbing, faster response, and smoother braking, all while enhancing load capacity and terrain adaptability.

4. Semi-Automated Navigation for Real-World Efficiency:

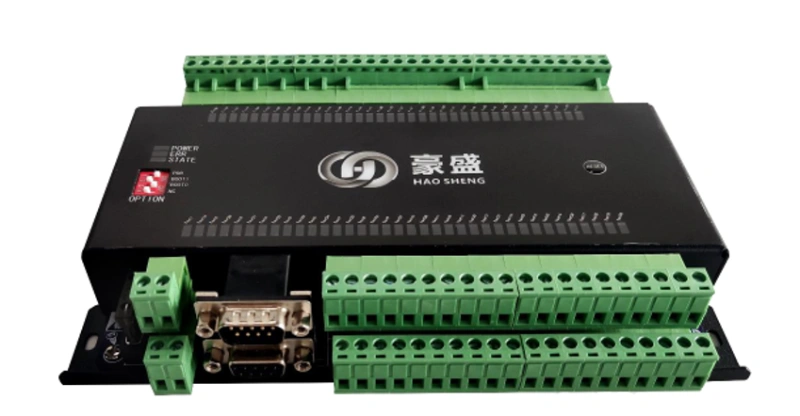

Instead of a costly full-automation setup, HENSEN provided a hybrid system with its self-developed Robot Control System:

- Magnetic track navigation + RFID positioning,

- Human-controlled loading/unloading at stations,

- Touchscreen interface, emergency stops, SICK laser radar, and edge detection for safety.

This design delivered automated long-distance movement between stations, significantly reducing manual labor without overcomplicating the system, keeping costs low and usability high.

Here comes the finished vehicles’ look.

Customer Feedback & Expansion:

The client praised HENSEN’s practical, user-focused solution. Within six months, they returned to order two additional 50-ton AGVs—a testament to the system’s reliability and value in large-pipe production workflows.

Why Choose HENSEN for Custom Heavy-Duty AGVs?

- ✅ 20+ Years of Experience in Heavy Industrial Transport

- ✅ Expert in Oversized Material Handling

- ✅ Proprietary AGV Steering & Control Technology

- ✅ Customizable Automation & Manual Integration

- ✅ Proven Success with 40-50 Ton Transport Solutions

Get Your Custom AGV Solution Today

Looking for a reliable, scalable AGV solution for large, heavy, or complex materials like pipelines or wind tower sections?

👉 Contact HENSEN for a tailored quote and project evaluation.