300-Ton Heavy-Duty AGV Successfully Tested and Delivered

As autumn approaches, HENSEN’s passion for innovation remains strong. Recently, HENSEN completed performance testing of a customized 300-ton Heavy-Duty AGV and delivered it to the customer for operation.

At HENSEN, our pride does not simply lie in the ability to customize AGVs with payload capacities of up to 800 tons. It also comes from more than 20 years of dedication to heavy-duty in-plant logistics, over 1,000 successful projects across 150+ industries, and our persistent commitment to solving real customer challenges.

This newly delivered 300-ton AGV, measuring 10 meters in length and 5.2 meters in width, was specially designed for transporting wind power nacelles. Its development journey spans more than a decade, evolving from 10t, 60t, 150t, 250t, and now to 300t, marking another milestone in HENSEN’s engineering breakthroughs.

Advanced Technology & Patented Innovation

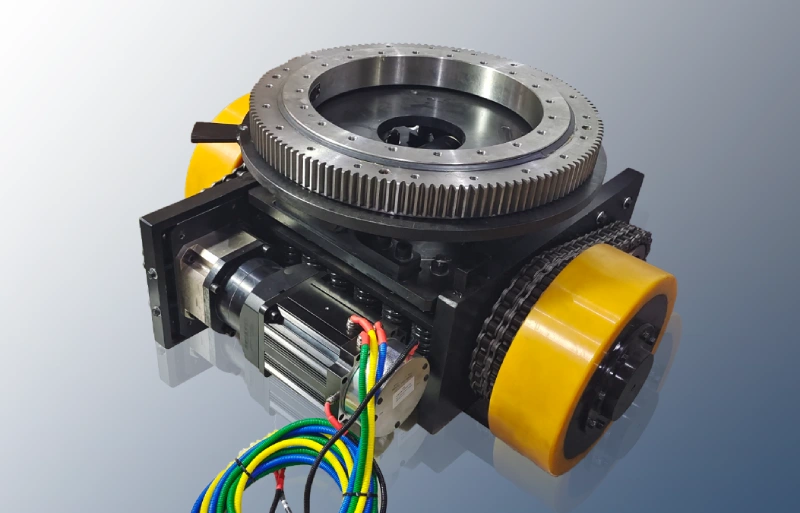

The AGV integrates HENSEN’s intelligent IoT vehicle system, advanced energy management, and multiple patented technologies in logistics automation. Key components include:

- High-performance gear reducers

- Lithium battery system

- Laser radar and sensors

- Polyurethane wheels

- HENSEN’s self-developed chassis and control systems

A core innovation is the HENSEN heavy-duty differential steering wheel set, which delivers powerful traction, high load capacity, and excellent adaptability to uneven ground. Equipped with a hydraulic load-balancing system, the AGV maintains stability even on irregular surfaces, significantly improving safety and operational reliability.

In addition, HENSEN’s self-developed mobile robot controller ensures precision and synchronization of wheel groups through proprietary algorithms. This enables advanced movement capabilities, including lateral, longitudinal, omnidirectional movement, 360° rotation, climbing, and obstacle avoidance.

Flexible Operation Modes: Automation & Manual

HENSEN heavy-duty AGVs can be configured for automatic navigation or manual remote control depending on customer requirements:

- Navigation Options: Magnetic tape, 3D laser, QR code, or hybrid laser + RTK

- System Integration: Seamless connection with ERP, MES, and WMS for automated task execution

- Manual Remote Control: Flexible deployment without route limitations

Our philosophy remains clear: “The right solution is the best solution.” Every AGV is tailored to the customer’s actual working conditions, ensuring practical value and maximum efficiency.

Wide Industry Applications

Beyond the wind power sector, HENSEN heavy-duty AGVs are widely used in:

- Energy Storage (battery cabinet transport)

- Power Plants (transformer handling)

- Precast Concrete Production

- Construction Machinery

- Shipbuilding

- Mining & Metallurgy

- Ports & Terminals

If your business is facing challenges in transporting oversized or ultra-heavy materials, HENSEN is your trusted partner for customized AGV solutions.

👉 Contact HENSEN today — your reliable manufacturer for heavy-duty AGVs, RGVs, and intelligent in-plant logistics solutions.