Custom 50-Ton Electric Coil Transporter for a Leading Aluminum Manufacturer

The non-ferrous metal processing industry, including the aluminum, copper, and steel coil sectors, is one of the many areas where HENSEN delivers reliable, heavy-duty handling solutions. This case study highlights a common challenge faced by many manufacturers: how to safely, efficiently, and cost-effectively transport heavy aluminum coils.

Customer Background: Top 3 Aluminum Processor in China

Our client is a subsidiary of CHALCO (China Aluminum Corporation) and ranks among the top three companies in China’s aluminum sheet and strip processing industry. With over 10 billion RMB in total assets and annual revenue, it operates large-scale production facilities and had long struggled with manual and inefficient coil transportation.

Challenges with Traditional Diesel Trucks

The client’s production involves handling two main types of aluminum coils:

- 🔘 Small coils: approx. 15 tons each

- 🔘 Large coils: approx. 20 tons each

Their current transport solution relied on rented 30-ton diesel trucks, which posed several problems:

- ❌ Overload risk: Carrying two coils (30–35 tons) exceeded safe limits

- ❌ Inefficient trips: Transporting one coil per trip doubled the operating frequency

- ❌ High operational cost: Truck rental + driver salary exceeded 200,000 RMB/year, excluding fuel

- ❌ Pollution: Diesel exhaust affected air quality and worker health

- ❌ Non-compliance: Contradicted the company’s goals for low-carbon and sustainable operations

With the rise of the industrial lithium battery sector, the client began seeking electric transport alternatives.

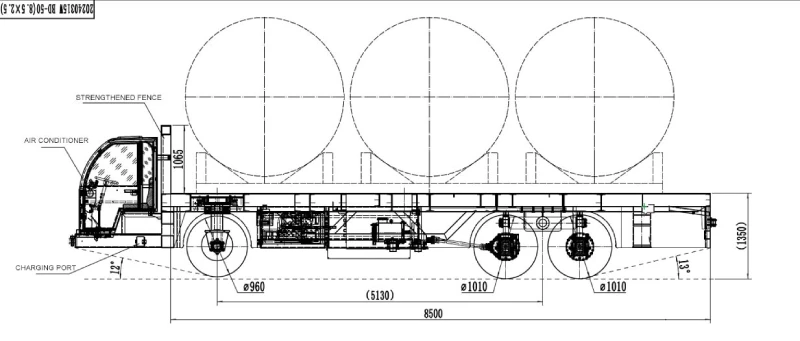

HENSEN’s Tailored Electric Solution: The BD-50 Coil Transporter

As a pioneer in electric heavy-duty material handling since 2005, HENSEN proposed a custom 50-ton electric coil transporter with a driver’s cabin, meeting the customer’s desire for manned operation.

✅ Key Features & Design Highlights:

- Target Efficiency: Designed to carry 3 coils per trip (2 small + 1 large), boosting efficiency

- Load Capacity: 50-ton rated load

- Deck Dimensions: 8500mm (L) × 2500mm (W) × ≤1350mm (H)

- Compact Body: More agile than traditional diesel trucks, ideal for factory use

- Heavy-Duty Build: Among very few manufacturers in China capable of 50+ ton electric vehicles, HENSEN now offers up to 80 tons

Powertrain & Safety Systems

- 🔋 Battery: 900Ah / 96V LiFePO₄ battery pack with BMS (Battery Management System)

- 🔧 Motors: Two 18.5kW three-phase asynchronous AC traction motors

- 🧠 Instrument Cluster: HENSEN’s self-developed 7” LED color dashboard

- Fault code display

- Telematics system

- Rear-view camera integration

- ❄️ Comfortable Cabin: Built-in air-conditioning system for driver comfort

On-Site Performance

After deployment, the BD-50 electric transporter significantly improved operational efficiency, reduced emissions, and supported the client’s move toward green manufacturing.

For customers requiring automated coil handling, HENSEN also offers a full range of AGV transport solutions:

50-Ton Steel Coil AGV

Copper Coil AGV for WANMA Cable

25-Ton Copper Strip AGV

3-Ton Stainless Steel Coil AGV

📸 Explore case photos and videos — or contact us now for more information and tailored designs.

Why Choose HENSEN Electric Coil Transporters?

- ✅ 20+ Years of Industrial Transport Experience

- ✅ Advanced Lithium Battery Technology

- ✅ Custom Design for Coil Size, Weight, and Workflow

- ✅ Drivered and Automated Models Available

- ✅ Reliable After-Sales Support & On-Site Deployment

Let’s Power Your Coil Handling with Green Technology

Whether you’re transporting aluminum, steel, copper, or stainless steel coils, HENSEN can provide efficient, clean, and customized solutions tailored to your needs.