Customized AGV/RGV Solutions for Efficient In-Plant Logistics

In the world of large-scale industrial manufacturing, automated, safe, and space-efficient in-plant material handling is critical. Many manufacturers face the challenge of moving heavy components between production stages—especially in facilities with tight space constraints and high-frequency workflows.

This is where HENSEN’s custom heavy-duty RGV and AGV transport solutions come in.

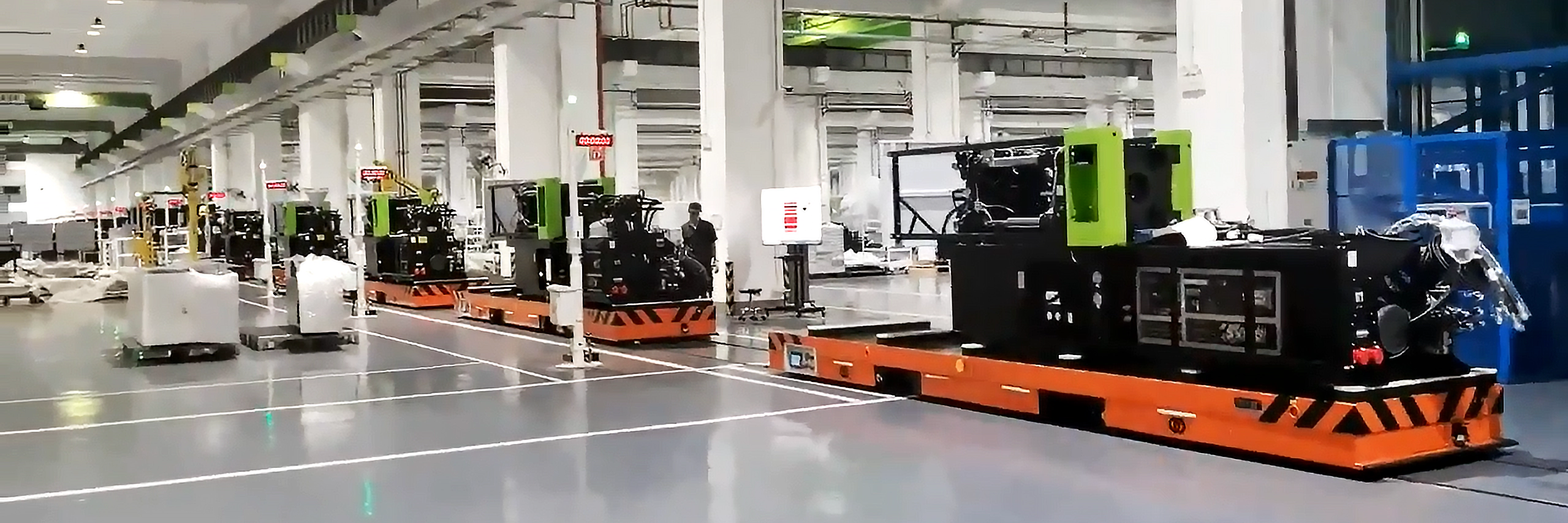

Project Overview: RGV System for Injection Molding Machine Manufacturer

Our client, a leading injection molding machine manufacturer in Guangdong, China, was building a new facility with two parallel production lines. Their goal is to automate the transfer of product components between designated workstations on both lines, with minimal manual operation and high transport frequency.

They launched a nationwide tender, seeking a reliable partner to deliver a complete turnkey solution—from system design and manufacturing to on-site implementation.

Challenges: Why Traditional Transport Methods Don’t Work

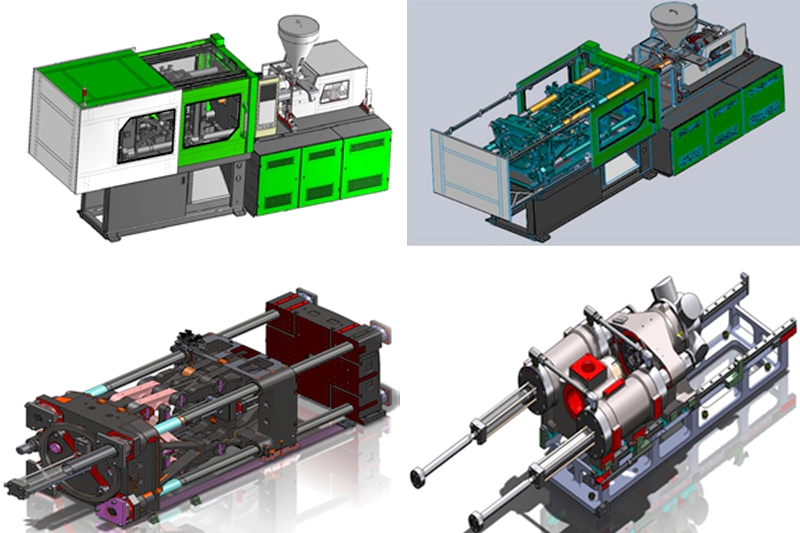

The components requiring transport measured up to 6 meters in length, 2 meters in width, and weighed between 3 to 12 tons. Based on this, HENSEN identified several key limitations:

- ❌ Not suitable for forklift transport

- ❌ Not suitable for crane-based lifting

- ❌ Not compatible with diesel or gas-powered vehicles due to factory cleanliness requirements

- ✅ Requires smooth-surface transport

- ✅ Needs stable, uniform speed during movement

- ✅ Must ensure worker safety at all times

- ✅ Transport cycle: every 11 minutes, minimum 38 trips per day

HENSEN’s Intelligent RGV-Based Transport Solution

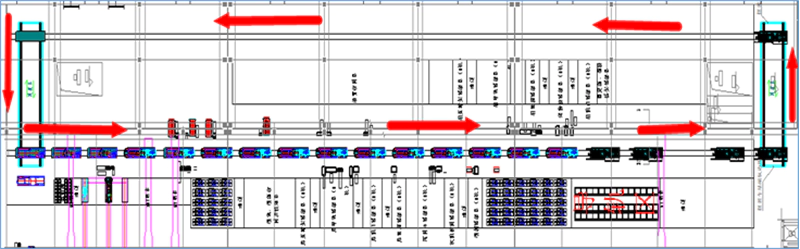

After thorough analysis of the production flow and an on-site survey, HENSEN proposed a closed-loop, multi-vehicle RGV system, optimized for fixed-route, high-frequency logistics in a constrained factory environment.

✅ System Architecture:

- 23 intelligent RGVs for horizontal long-range transport

- 2 rail-mounted transfer shuttles (rail changers) for track switching

- Dual-track layout: long tracks alongside both production lines, short vertical tracks at either end

- Centralized dispatching & monitoring system with touch-screen control

This design eliminates the need for rotary turntables, saving on infrastructure costs and increasing space utilization.

How It Works: A High-Efficiency Loop

- Components produced on the first line are loaded onto RGVs.

- RGVs carry the items to the specified station on the second production line.

- After unloading, the RGV proceeds to the vertical track.

- A transfer shuttle moves the RGV to the opposite track.

- The RGV is ready for the return trip—forming a closed-loop transport cycle.

This intelligent RGV network significantly boosts efficiency, minimizes downtime, and reduces labor dependency.

Custom-Designed Vehicles & Control System

HENSEN delivered:

- 🔧 Heavy-duty RGVs engineered specifically for the client’s component specs

- 🚉 Track-changing shuttles for seamless rail switching

- 🧠 A central dispatching platform with a large-format touchscreen interface for real-time operations control

All hardware and software were designed, manufactured, and integrated in-house by HENSEN, ensuring a seamless, scalable solution.

Why HENSEN?

- ✅ 20+ Years in Intelligent Industrial Transport

- ✅ Full In-House Design, Production, and Deployment

- ✅ Custom Solutions for AGV/RGV Systems

- ✅ Proven in Complex Factory Environments

- ✅ Turnkey Delivery with Full Support

Need Smart Transport for Your Production Line?

If your facility requires reliable, automated material handling for oversized components, or you’re exploring AGV/RGV systems to improve efficiency, HENSEN is your trusted partner.

📩 Contact us today to learn how we can tailor a solution for your manufacturing process.