Customized AGV System to Enable Automotive Line Automation and Upgrade

As Industry 4.0 continues to reshape global manufacturing, many companies in automotive production, vehicle modification, and special-purpose vehicle manufacturing are actively investing in smart factory upgrades. One of HENSEN’s projects demonstrates how a tailored AGV-based production line can significantly improve efficiency, flexibility, and sustainability.

🔧 Project Background: Intelligent Transfer Line for Vehicle Retrofit Factory

Our client specializes in converting finished vehicles into ceremonial cars, business vehicles, and other specialized formats. Previously, the factory lacked a standardized transfer system and relied on driving vehicles between stations, which:

- Added unwanted mileage, lowering resale value

- Required workers to multitask between driving and modification, reducing productivity

- Made it difficult to access the chassis for welding or modification

- Rendered vehicles immobile once their drivetrain or structure was altered

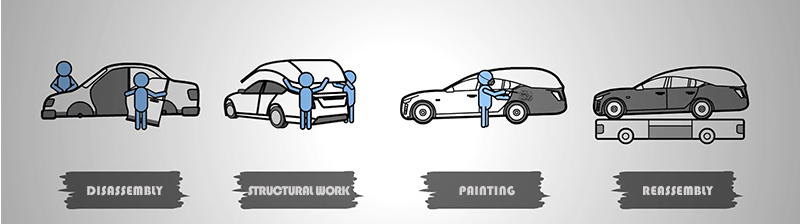

With each vehicle requiring multiple steps—disassembly, structural work, painting, reassembly—a flexible, intelligent AGV transport system became essential for streamlining workflow.

HENSEN’s Intelligent AGV Transport System Design

After evaluating the client’s environment, production rhythm, and vehicle weight, HENSEN proposed a platform-style AGV system with centralized scheduling, enabling two full automotive lines to operate automatically.

✅ System Overview:

Environment: Indoor vehicle factory

Working Schedule: 8-hour daily shift

AGV Type: Platform-based AGV transporters

Payload Capacity: 4 tons

Dimensions: 2600mm × 1200mm

Drive Motor: Permanent magnet synchronous motor

AGV Controller: Industrial-grade 32-bit HENSEN controller (–10°C to +60°C), with strong I/O isolation and high-speed computing

Power Supply: Lithium battery with advanced BMS

Charging:

2 x automatic chargers per line

1 x mobile charger as backup

Charging time (10% → 95%): ~2.5 hours

Navigation & Positioning:

Ground magnetic strips + magnetic sensors

RFID sensors for precision docking

Total Workstations: 20 (10 per line)

Parking Accuracy: ±10mm

Obstacle Avoidance: Laser scanner + touch sensor

Speed:

Manual: 0–25 m/min (adjustable, soft start)

Auto: 0–12 m/min

Control Modes:

Remote Control – Forward/back via remote

Manual Button – Operators press the onboard button to move to the next station

Central Command – AGVs auto-run based on browser-based central instructions

Results: Efficient, Smart, Sustainable

This smart AGV production line:

- Eliminated manual driving and reduced vehicle wear

- Simplified multi-step modification processes

- Increased worker safety and productivity

- Delivered an energy-efficient and eco-friendly operation

- Provided a strong foundation for the client’s market expansion and order growth

Whether you’re launching a new smart line or upgrading your traditional workflow, HENSEN delivers custom-built AGV systems that align with your production needs and factory environment.

Looking to Upgrade Your Production Line with Smart AGV Systems?

HENSEN offers professional consultation, engineering, and integration services for:

- Automotive assembly lines

- Special-purpose vehicle production

- Industrial automation retrofits

- Green, efficient transport solutions

📩 Contact us now for a tailored AGV solution that transforms your production line.