From Shipyards to Wind Farms – One Solution for the Longest, Heaviest Loads

In Taizhou, Jiangsu, one of China’s leading shipbuilding hubs, heavy industrial manufacturers face a common challenge:

How to safely and efficiently transport ultra-long materials—such as ship propulsion shafts, wind turbine blades, or 30-meter steel beams—through complex factory environments without disrupting production.

This challenge is not unique to shipbuilding. Similar needs arise in:

- Wind energy – transporting 60–80m turbine blades

- Steel pipe manufacturing – handling large-diameter, long pipes

- Rail transit – moving full-length train car bodies

- Steel structure fabrication – transferring long beams and bridge segments

The Pain Points of Ultra-Long Load Handling

- Oversized dimensions make turning and maneuvering difficult

- Uneven weight distribution risks load instability

- Limited plant space restricts use of large, single-body transport vehicles

- High customization costs for extra-long AGVs with low utilization rates

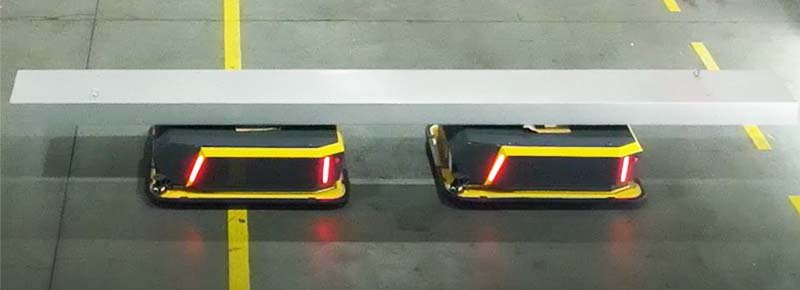

HENSEN’s Answer: Dual-AGV Synchronization Technology

Instead of relying on a single oversized transporter, HENSEN deploys two independent AGVs operating in perfect synchronization, each carrying one end of the load.

Key Advantages Over Traditional Long-Body Vehicles:

- 🚀 Higher ROI – Standard AGVs can be used separately for other tasks

- 🛠 Flexible deployment – Easily reconfigured for different load lengths

- 🔧 Reduced manufacturing cost – No need for a custom ultra-long chassis

- 📦 Better space utilization – Ideal for narrow aisles and tight factory layouts

How the Dual-AGV System Works

A synchronized AGV system includes:

- Master & Slave AGVs – One unit leads, the other follows

- Central Control System – Coordinates movement in real time

- High-Precision Positioning – Laser, vision, or encoder-based tracking

- Wireless Communication – 5G or Wi-Fi for millisecond-level signal exchange

Performance Highlights:

- Max Load: Up to 800 tons combined

- Precision: ±10 mm positioning, ≤0.5° angular deviation

- Mobility: Forward, reverse, lateral movement, synchronous turning

- Slope Capability: Up to 3° (load-dependent)

- Range: 80–100 m Max wireless sync distance

Industry Applications

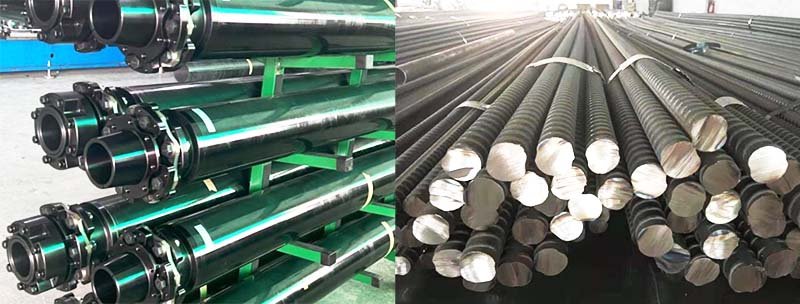

Shipbuilding

- Propulsion shafts, deck cranes, hull sections

- Example: Two 15-ton AGVs work together to handle 30-ton loads, ignoring center-of-gravity offset

Wind Power

- Turbine blades, tower sections, and nacelle components

- Example: Dual 60-ton AGVs transporting blades over 70m long

Steel Pipe & Structure Manufacturing

- Large-diameter pipelines, bridge beams, and prefabricated modules

- Example: Compact 2-ton AGV pairs for long steel profiles in small workshops

Rail Transit

- Train car bodies, bogie frames, and long rail components

Why Industry Leaders Choose HENSEN

- 20+ years of heavy-duty material handling expertise

- 1–800 ton load capacity range

- Proven since 2020 in multiple industries worldwide

- Turnkey service – From design and manufacturing to installation and global support

Customer ROI at a Glance

- 🔻 Reduce investment vs. building oversized AGVs

- 📈 Increase equipment utilization with dual/single AGV flexibility

- 🕒 Shorten transfer time by up to 40%

- 🛡 Enhance safety with synchronized movement and load stability control

FAQ – What Clients Ask Most

Q: Can dual AGVs operate outdoors?

A: Yes, with weatherproofing and terrain-specific wheels.

Q: What’s the maximum length that can be transported?

A: Over 80m, depending on AGV capacity and load type.

Q: How is safety ensured?

A: The system uses redundancy in positioning, load sensors, and emergency stop protocols.

Partner with HENSEN for Your Oversized Load Challenges

From shipyards to wind farms, from steel pipe mills to rail transit assembly lines, HENSEN’s synchronized dual-AGV technology delivers safe, efficient, and cost-effective transport for ultra-long and heavy materials.

📩 Contact our engineering team today for a free site assessment and custom proposal.