Quality Awareness Begins in the Mind, Responsibility Lies in Action

As a custom manufacturer of heavy-duty AGVs and intelligent material handling vehicles, HENSEN understands that quality means reliability — and reliability defines trust.

Every October, Hangzhou HENSEN Technology Co., Ltd. celebrates its annual “Quality Month”, a company-wide initiative to strengthen awareness, refine processes, and embed quality into every step of production.

In 2025, under the theme “Quality Awareness Begins in the Mind, Responsibility Lies in Action,” HENSEN organized a series of activities, including training, education, quality competitions, and improvement campaigns, encouraging every employee to take ownership of quality.

The goal: to create a strong corporate culture of “Everyone Values Quality, Everyone Creates Quality, and Everyone Enjoys Quality.”

1. United Launch — Building Shared Commitment

At the beginning of October, HENSEN held an official launch ceremony for the 2025 Quality Month.

During his keynote speech, the General Manager emphasized:

“Quality is the lifeline of our enterprise, the core value of our brand, and the foundation of our competitiveness in the global market.”

He called on all employees to uphold the “Quality First” principle and implement responsibility at every level—from design and machining to assembly and testing.

All staff signed their names on the commitment banner, symbolizing their shared pledge to uphold quality excellence.

2. Comprehensive Actions — Measurable Results

Throughout the month, each department actively participated, achieving impressive outcomes:

📘 Training for Awareness and Skills

A total of 8 quality training sessions were held, covering topics such as quality awareness, case analysis, and problem prevention.

Departments, including technical, machining, welding, and final assembly, organized targeted workshops to enhance employee competence and prevention capability.

💡 Employee Suggestions for Continuous Improvement

The campaign received 36 employee suggestions, with 24 officially adopted — a 67% adoption rate.

Ideas focused on process improvement, tooling optimization, and defect prevention, demonstrating strong ownership, creativity, and accountability among staff.

🔍 Special Inspections and Process Optimization

Led by Vice General Manager Mr. Yang, the company conducted three rounds of on-site quality inspections, identifying and resolving key issues while optimizing workflows and standardizing production processes.

⚙️ QCC Projects — Tackling Real Challenges

Dedicated Quality Control Circles (QCCs) were formed across departments to address typical quality problems.

Five improvement projects were successfully completed, focusing on drill jig optimization, paint coating quality, and communication stability, resulting in tangible quality enhancements.

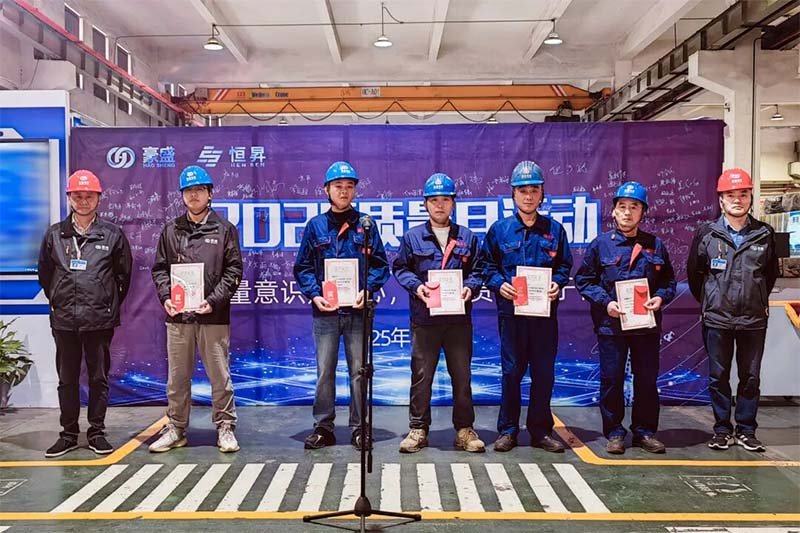

3. Recognizing Excellence — Inspiring Progress

At the Quality Month Award Ceremony, HENSEN honored teams and individuals who demonstrated outstanding performance:

Outstanding Team: Machining Workshop

Best QCC Groups: Machining Workshop, Final Assembly, Technical Department

Quality Pacesetters: Cheng Xiaopeng, Ma Aijun, Sun Qiang, Li Zhao, Ma Yupeng, Li Hangyu, Zhang Yanzhen, Ding Aoxing

Proposal Excellence Award: Lu Yang, Li Zhao, Si Nian, Zhang Yanzhen, Ren Haiqing

4. Looking Forward — Continuous Improvement, Lasting Impact

During the closing ceremony, General Manager Mr. Sun remarked, “Quality Month may have ended, but the pursuit of quality is endless.” He outlined HENSEN’s next steps to continuously strengthen:

Quality awareness and corporate culture

Implementation of standardized management systems

Targeted problem-solving and root-cause analysis

Ongoing innovation in quality improvement

Supplier quality management and risk control

HENSEN aims to establish a long-term quality improvement mechanism, making every day a “Quality Day.”

Quality Creates Value, Craftsmanship Shapes the Future.

From custom heavy-duty AGV manufacturing to intelligent in-plant logistics systems, HENSEN’s commitment to excellence has never wavered.

By practicing the principle of “Scientific management, quality excellence, customer satisfaction, and continuous improvement,” the company continues to lead the development of smart logistics and heavy-duty automation solutions.

At HENSEN, every innovation, every weld, and every vehicle carries one promise — to deliver quality you can trust.

Leave a comment